The Importance of Safety Protocols for Heavy Equipment

Operating heavy equipment requires precision because even a small mistake can have major repercussions. This underscores the importance of safety protocols, which are crucial for protecting people and ensuring smooth operations. In this blog, we’ll provide insights into the significance of safety protocols for heavy equipment.

Understanding the Role of Safety Protocols in Heavy Equipment Operation

Safety protocols are about prevention. They are meticulously designed to anticipate and mitigate risks before they become incidents. This proactive approach is crucial in environments where heavy equipment operates, as the potential for accidents is high. Technological advancements have significantly bolstered safety measures. From real-time monitoring systems to automated emergency shutdowns, technology plays an important role in ensuring operations run smoothly and safely.

Equally important is the role of training and awareness. Operators should be well-versed in safety protocols. This knowledge is a critical component of safety, ensuring that every decision is informed by best practices.

How Do Safety Protocols Reduce Downtime and Save Costs?

Implementing strict safety protocols might seem like an upfront investment, but the long-term benefits outweigh the initial costs. Businesses can significantly reduce downtime by minimising the risk of accidents. Every incident involving heavy equipment can lead to halted operations, which in turn affects productivity and deadlines. Safety protocols act as a preventive measure, ensuring that operations proceed without costly interruptions.

Moreover, the financial implications of ignoring safety protocols can be substantial. From repair costs for damaged equipment to compensation and legal fees in the event of workplace accidents, the expenses can quickly add up. By adhering to established safety measures, businesses can avoid these unforeseen costs, ensuring that resources are allocated efficiently and effectively.

Electrical Safety: The Lifeline of Heavy Equipment Operations

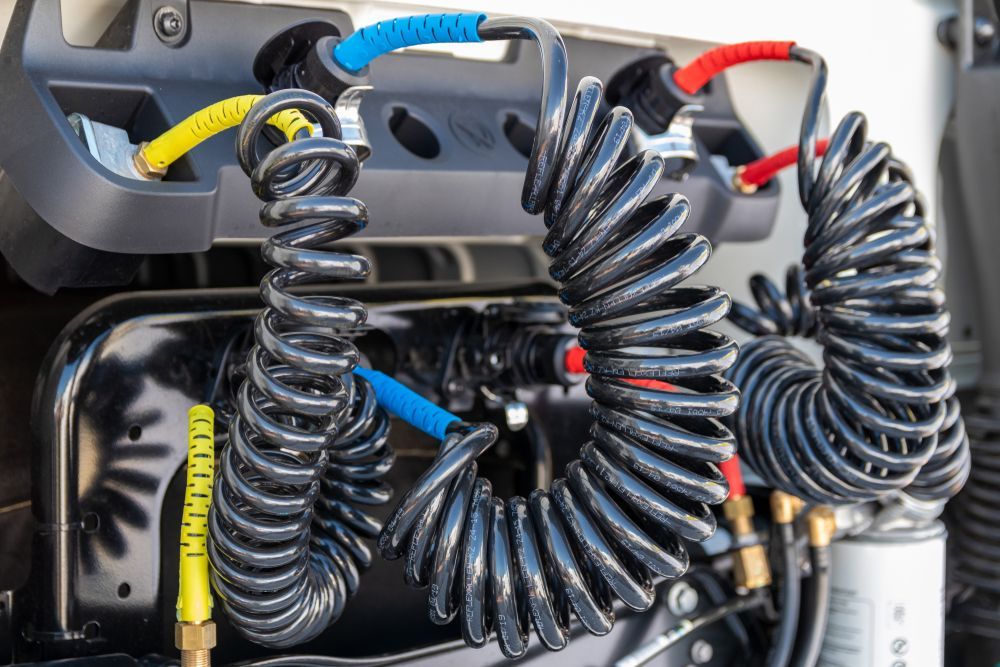

Electrical safety forms the cornerstone of heavy equipment operations, acting as a critical lifeline that ensures the seamless and secure functioning of machinery. Faulty wiring, improper connections or neglected maintenance can lead to catastrophic failures. Therefore, a rigorous approach to electrical safety, encompassing regular inspections, timely repairs and adherence to safety standards, is essential to prevent accidents and ensure the longevity of the equipment.

Moreover, the integration of sophisticated electronic systems into heavy machinery has heightened the importance of electrical safety. These systems, which include navigation, monitoring and control technologies, rely heavily on the electrical system's reliability. A single electrical fault can render advanced features useless, compromising safety features and operational efficiency. Consequently, operators and maintenance teams must be well-versed in electrical safety practices, understanding the intricacies of their machinery's electrical systems.

Connect with Our Heavy Equipment Auto Electricians

The importance of safety protocols in the operation of heavy equipment cannot be overstated. They are essential not just for the well-being of individuals but for the overall efficiency and cost-effectiveness of operations.

At Buckland Auto Electrical, we pride ourselves on our commitment to safety, ensuring that every service we provide adheres to the highest standards of safety and excellence. Our team ensures your heavy equipment operates at its best, with safety protocols that protect everyone involved. Contact our heavy equipment auto electricians in Illawarra today!