Electricians Overcoming Obstacles In Remote Mining Sites

Maintaining operational efficiency and safety in remote mining sites is no small feat. As contractors and builders, you understand the importance of keeping machinery running smoothly in challenging environments. From extreme weather conditions to equipment failures, electricians in the

mining industry are constantly on their toes, ensuring that operations run smoothly and safely. In this blog, we’ll explore the various challenges electricians face and how they overcome them to keep mining sites operational.

The Harsh Environment

One of the most significant challenges electricians face in remote mining sites is the harsh environment. These areas are often exposed to extreme temperatures, high humidity and corrosive conditions, which can affect electrical equipment. To combat these conditions, electricians use specialised tools and materials designed to withstand harsh environments. For instance, weatherproof enclosures and corrosion-resistant wiring are standard in these settings, ensuring that electrical systems remain functional despite the environmental stresses.

Limited Access to Resources

Access to resources and spare parts can be limited in remote locations. This means that electricians need to be exceptionally resourceful and skilled in improvisation. They often have to work with what’s available, finding innovative solutions to keep equipment operational. Regular maintenance and thorough inspections are crucial, as they help identify potential issues before they become major problems. Electricians can minimise downtime and maintain productivity by anticipating and preparing for possible failures.

Safety Concerns

Safety is a major concern in mining operations and electrical work adds another layer of risk. Electricians must adhere to stringent safety protocols to protect themselves and their colleagues. This includes wearing appropriate personal protective equipment (PPE), following lockout/tagout procedures and conducting regular safety training. Moreover, using advanced diagnostic tools helps identify electrical faults early, reduces the risk of accidents and enhances overall safety on site.

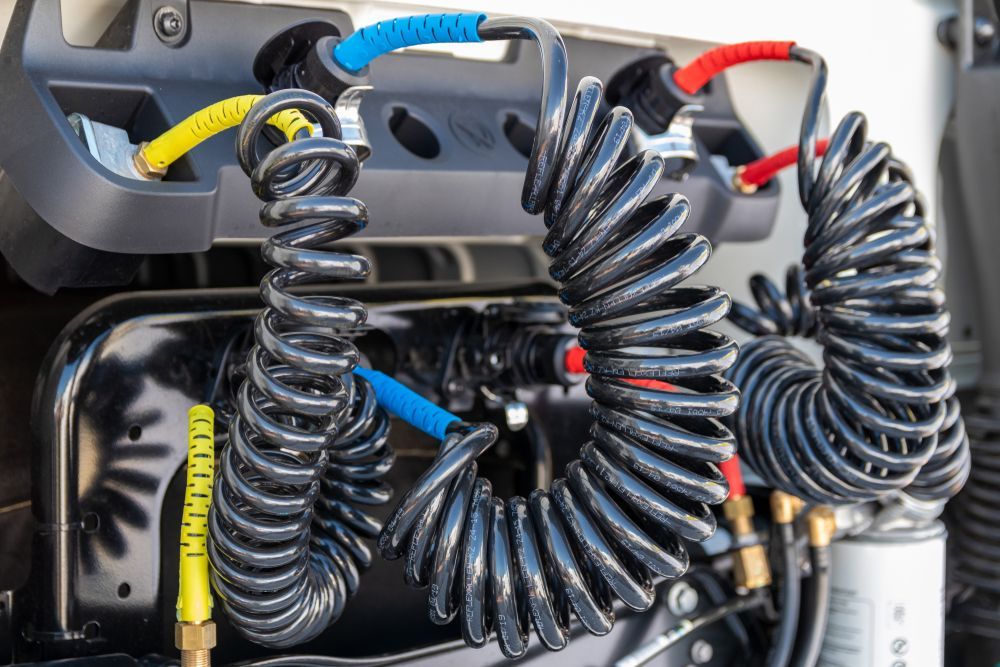

Complex Machinery

Mining sites are home to some of the most complex and heavy-duty machinery, such as earthmoving equipment and drilling rigs. These machines rely heavily on sophisticated electrical systems for operation. Electricians specialising in heavy-duty auto electrics are trained to handle these complexities, performing tasks such as installing, maintaining and repairing electrical systems in heavy machinery. Their expertise ensures the equipment operates efficiently, minimising the risk of costly breakdowns.

Isolation And Communication

Isolation is another significant challenge in remote mining sites. Electricians often work in isolated areas, far from the support and infrastructure in more urban settings. Effective communication becomes crucial in such scenarios. Many mining operations utilise advanced communication systems, including satellite phones and two-way radios, to ensure electricians can stay in touch with the main office and promptly report any issues.

Training And Adaptability

The dynamic nature of mining operations requires electricians to be highly adaptable and continuously update their skills. Ongoing training programs are essential, covering the latest advancements in electrical technology and safety practices. Electricians must stay informed about new regulations and industry standards to ensure compliance and optimal performance.

Maximise Efficiency with Our Professional Mining Electrical Services

Electricians play a crucial role in the smooth operation of remote mining sites, tackling various challenges with skill and resilience. At

Buckland Auto Electrical, we provide high-quality services for

earthmoving equipment auto electricians in Illawarra and heavy-duty auto electrics.

Our expert team ensures your mining operations run efficiently and safely.

Contact us for reliable, high-quality solutions tailored to meet the demanding needs of remote mining sites.