5 Essential Skills Every Mining Equipment Electrician Needs

In the dynamic and demanding world of mining, the efficiency and reliability of heavy machinery are crucial to the success of operations. When a massive haul truck or an excavator stops working due to an electrical issue, it can cause significant delays, impacting productivity and profitability. This is where the expertise of

mining equipment electricians becomes invaluable. They ensure the electrical systems in mining vehicles are functioning optimally. In this blog, we'll explore the five essential skills every mining equipment electrician needs.

1. Deep Understanding of Electrical Systems in Heavy Machinery

Mining equipment electricians should possess a thorough knowledge of electrical systems in heavy machinery. They work with a diverse array of equipment, from loaders and excavators to haul trucks, each with its own unique electrical setup.

In-depth knowledge of these systems ensures that electricians can effectively troubleshoot and maintain machinery. For instance, understanding the specific electrical requirements and configurations of different machinery allows electricians to pinpoint faults accurately.

2. Proficiency in Diagnostic Tools and Techniques

Modern mining machinery is equipped with advanced diagnostic systems, requiring electricians to be proficient in using these tools. They should be skilled in using diagnostic software and tools. This allows for quick identification of issues, reducing downtime and increasing efficiency.

Understanding how to interpret the data from these tools is equally important. Electricians should be able to analyse diagnostic information, correlate it with the symptoms observed and devise effective repair strategies.

3. Strong Problem-Solving Skills

Electricians often encounter issues that require innovative solutions and quick thinking. For example, an unexpected electrical fault in a critical piece of equipment can halt operations, leading to significant financial losses. In such situations, the electrician's ability to think quickly, draw on their experience and apply creative solutions becomes invaluable.

Furthermore, problem-solving in this context often involves collaboration with other team members, such as mechanical engineers and operators, to ensure a holistic approach to resolving issues.

4. Knowledge of Safety Standards and Regulations

Given the high-risk environment, safety is critical in mining operations. So, mining equipment electricians should ensure all electrical work complies with safety standards. This includes following guidelines for the safe installation and maintenance of electrical systems, using appropriate personal protective equipment and adhering to lockout/tagout procedures to prevent accidental activation of machinery.

Moreover, ongoing training is essential to stay updated on the latest safety practices and regulatory changes. Electricians should participate in regular safety drills and refresher courses to reinforce their knowledge and skills.

5. Expertise in Component Installation and Maintenance

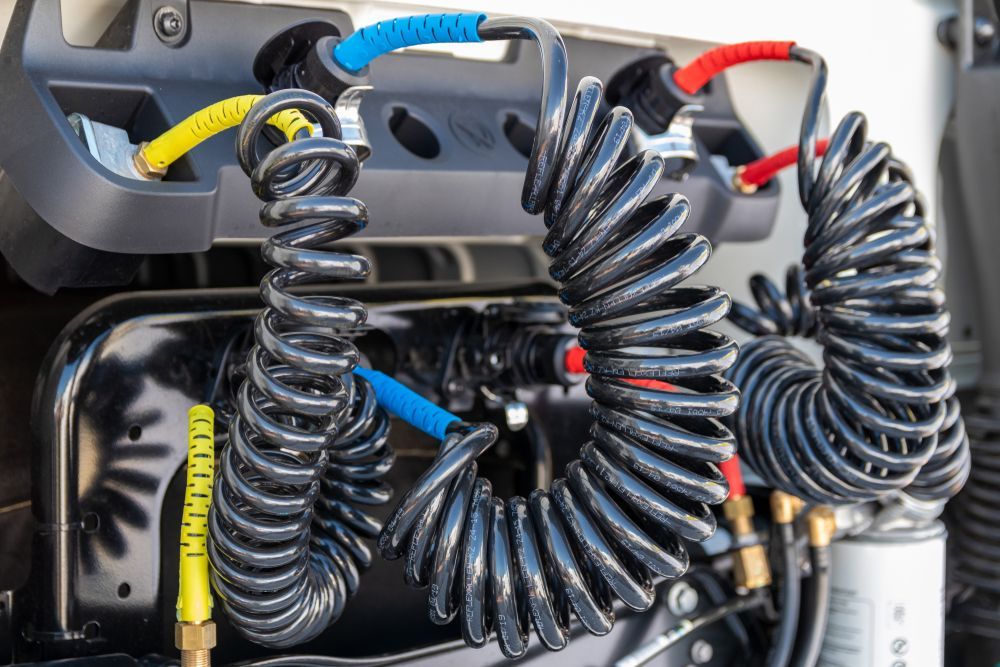

Installing electrical components in mining equipment requires a high level of expertise. This involves the precise installation of electrical components, such as wiring, sensors and control systems. Electricians should ensure that installations are carried out correctly to prevent future issues and optimise the performance of the equipment.

Regular maintenance is essential to keep mining equipment running smoothly. This includes routine inspections, cleaning and replacing worn-out parts. Electricians should be adept at scheduling and performing maintenance tasks to extend the lifespan of the machinery.

Looking for a Heavy-Duty Auto Electrician in Wollongong?

At

Buckland Auto Electrical, we understand the critical role that electricians play in maintaining the efficiency and safety of mining operations. Our team possesses all these essential skills.

Get in touch with our heavy equipment auto electricians in

Wollongong today!

SITE LINKS

our services

LOCATIONS

COMPANY INFORMATION

0408 029 224

Manager (Out of Hours)

bucklands@bpm-services.com.au

ABN -

34 132 043 666

RTA Authorisation Number - AU13661

TRADING HOURS

- Monday

- -

- Tuesday

- -

- Wednesday

- -

- Thursday

- -

- Friday

- -

- Saturday

- Closed

- Sunday

- Closed

24hr Emergency Call Out For Plant Machinery